Introduction

In today’s technologically advanced world, the integration of IoT (Internet of Things) into power systems has revolutionized how we manage and monitor electrical energy. This blog post will guide you through the development of a smart three-phase inverter using NodeMCU, Arduino Nano, and IoT technology. This system enhances the efficiency and reliability of power conversion and allows for remote monitoring and control via IoT platforms, making it ideal for both industrial and residential applications.

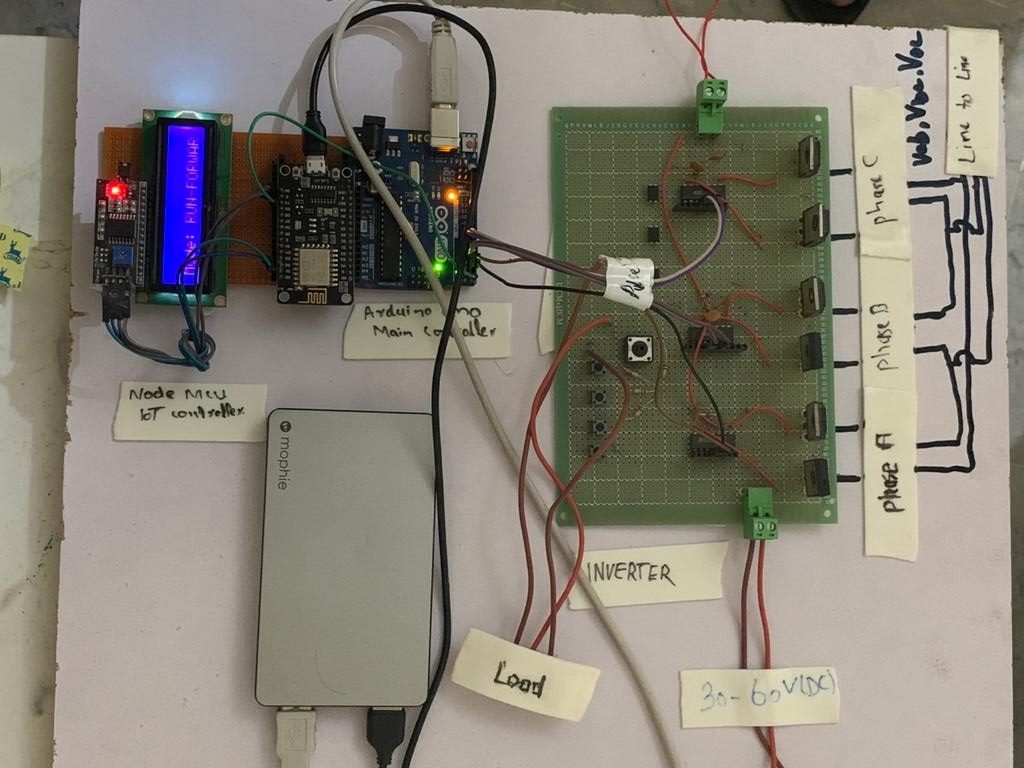

Components Used

1. Arduino Nano Serves as the core controller for the inverter, handling signal processing and control logic.

2. NodeMCU (ESP8266) Provides Wi-Fi connectivity, enabling remote monitoring and control of the inverter through IoT platforms.

3. IoT Controller Interfaces with the NodeMCU to transmit data to a cloud-based IoT platform.

4. LCD Display Provides real-time visualization of the inverter’s operating parameters.

5. Power Electronics Components Includes MOSFETs or IGBTs, gate drivers, and filters to convert DC to three-phase AC.

6. Sensors Current and voltage sensors for monitoring the inverter’s output and feedback control.

7. Buck Converter Regulates the voltage levels to power the Arduino Nano and NodeMCU.

8. Capacitors and Inductors Used in filtering and stabilizing the output waveform.

System Operation

1. Signal Generation and Control The Arduino Nano generates PWM (Pulse Width Modulation) signals to drive the power electronics, converting DC to three-phase AC power.

2. Data Acquisition Sensors measure the output voltage and current, providing feedback to the Arduino Nano for real-time control adjustments.

3. IoT Integration The NodeMCU transmits operational data (such as output voltage, current, and system status) to an IoT platform via Wi-Fi.

4. Remote Monitoring and Control Users can access the IoT platform through a web interface or mobile app to monitor the inverter’s performance and make adjustments as needed.

5. Display Interface The LCD provides immediate feedback on the inverter’s status and operational parameters.

Key Features

1. Real-Time Monitoring Continuous tracking of the inverter’s output and performance through sensors and IoT integration.

2. Remote Accessibility Enables users to monitor and control the inverter from anywhere using an internet connection.

3. User-Friendly Interface The LCD display and IoT platform offer easy access to critical information and system controls.

4. Enhanced Efficiency Feedback control mechanisms ensure optimal operation and high efficiency of the inverter.

5. Safety and Reliability Real-time monitoring helps in early detection of faults, improving the system’s reliability and longevity.

Benefits

– Increased Operational Efficiency Optimizes power conversion with real-time feedback and control.

– Enhanced Monitoring Capabilities Provides detailed insights into system performance, helping in proactive maintenance and troubleshooting.

– Remote Control Offers the convenience of controlling the inverter from remote locations, ideal for inaccessible installations.

– Improved Reliability Continuous monitoring and real-time adjustments reduce the risk of system failures.

– Scalability Easily expandable to include more functionalities or integrate with other smart devices in an IoT ecosystem.

Conclusion

The development of a smart three-phase inverter using Arduino Nano and NodeMCU with IoT capabilities presents a significant advancement in power electronics. By integrating real-time monitoring, remote control, and enhanced efficiency, this system provides a robust solution for various applications, from industrial machinery to residential energy systems.